ball end mill feeds and speeds

Professional Design Low Consumption 8TH Wood Peanut Shell Straw Pellet Manufacturing Plant Project In China. Metalworking Fabrication Speed Feeds.

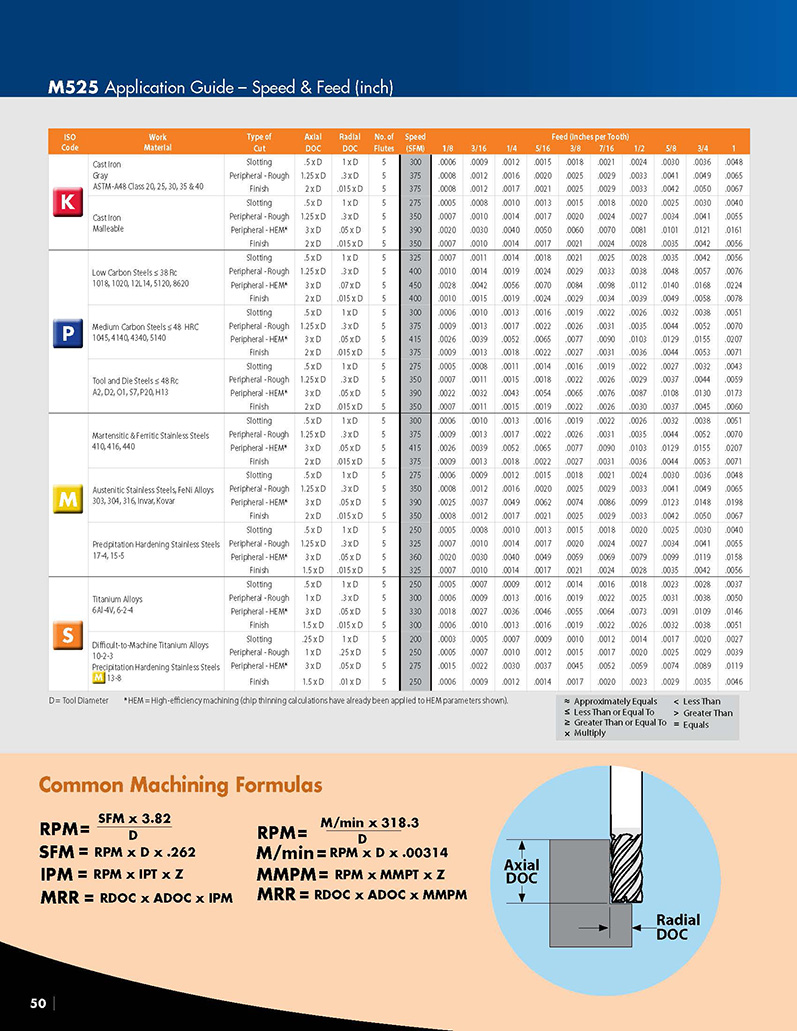

Common Formulas For Milling Operations Speed Feed Sfm Ipt Mrr Dapra Corporation

Aluminum Aluminum Alloys 2024-T4T6 2014 6061-T6T651.

. Speeds and feeds speeds and feeds for boring tools material plastic magnesium aluminum copper brass bronze cast iron steel titanium stainless nickel monel inconel waspaloy hastelloy type teflon nylon phenolic glass filled azamezzehk 2021 thru 6061 101-707 834-978 gray ductile malleable 1005-1029 1030-1055 1060-1095 10l45-10l50 12l13-12l15. For TiN and TiCN coated tools increase speed by up to 20 with the feed rate unchanged. Calculations use the desired tool diameter number of teeth cutting speed and.

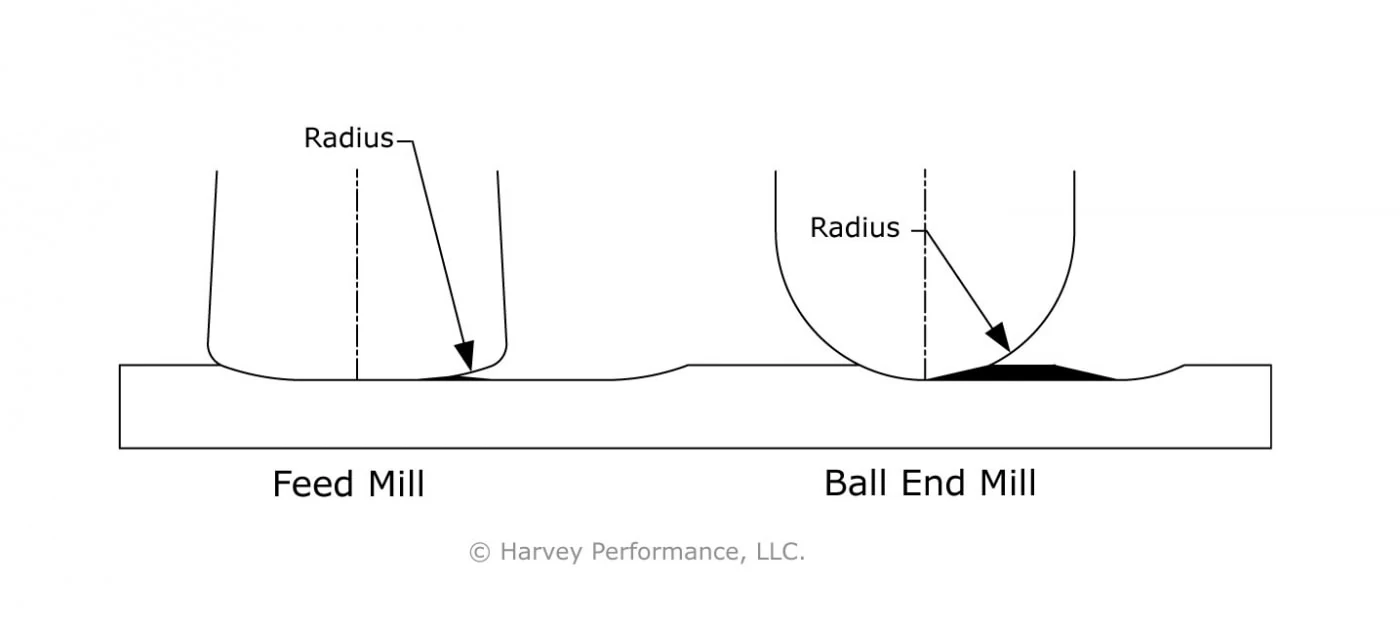

Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth such as an end mill or face mill. Keyway Tolerances End Mill. I am creating a new calculator based on your feedback.

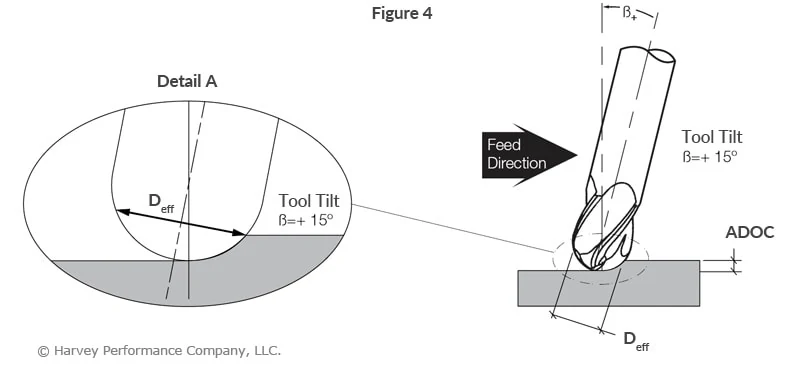

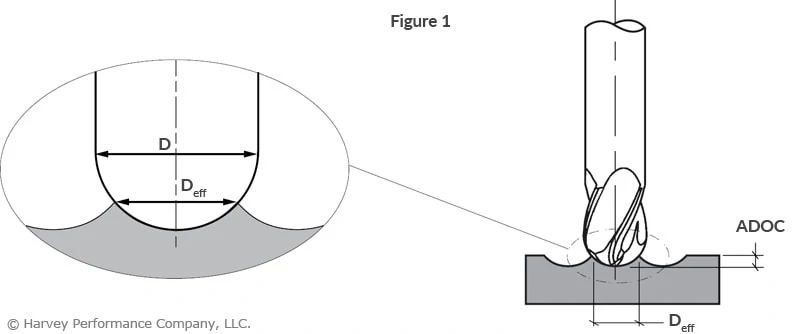

Angle Double Single End Mill. If possible it is highly recommended to use ball nose end mills on an incline ß to avoid a 0 SFM condition at the center of the tool thus increasing tool life and part finish Figure 4. The specialized barrel tool design is engineered to significantly improve many traditional ball end.

PREMIUM CARBIDE MILL SPEED FEED 4-F1ute - Ball Nose End Mills CHARTS Aluminum Alloys Carbon Steels Alloy Steels Tool Steels 285-275 Bhn Cast Iron RPM 7300 4900 3600 2900 2400 1800 1430 1200 1000 920 810 730 O3D Material Hardness Diameter 332 18 532 316 14 516 38 12 916 58 1116 1316 Carbon Steels. Tapered end mill usage can be tricky if the proper settings. TAPERED END MILLS HIGH SPEED STEEL FEED PER TOOTH ROUGHING AND FINISHING Material.

For TiAIN coated tools speeds may be increased by up to 50 with the feed rate unchanged. Specialized high performance. Determine the spindle speed RPM and feed rate IPM for a milling operation as well as the cut time for a given cut length.

031 carbide ball end mill feeds and speeds. Stepover Radial mm -. Do not use flood coolant with hard mills.

Solid carbide end mills for aluminum. Ceramic Hi- Feed Indexable End Mill 9 MM IC Insert double sided inserts 4 Cutting edge insert 4 indexes060 Max. WORKPIECE MATERIAL TYPE OF CUT SURFACE SPEED SFM FEED PER TOOTH BY END MILL DIAMETER 18 14 12 34 1.

Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth such as an end mill or face mill. Feeds - IPT inchestooth and MMPT mmtooth Material. The seven-flute design allows for superior finishes at higher speed and feed rates versus 5 and 6 flute tools.

Feed Hammer Mill. I will be using a 031 stub carbide ball endmill and a forth axis. Performance carbide endmills tapered end mills custom end mills and milling cutting tools at Conical Tool Home.

Milling Speed and Feed Calculator. 26082022 Doesnt really matter the speeds and feeds. Recommended Cutting SpeedsFeeds Recommended Cutting Speeds for Dapra Ball Nose Cutters MATERIAL GROUP EXAMPLE F1T1 uncoated FPO FP-GLH FP-HMTS PCD Geometry FPT PLAIN STEELS 3C 1008 1018 12L14 300-600 700-1100 800-1200 800-1200 NR.

Speeds and Feeds Master Library of Harvey Tools entire tool line up of Specialty End Mills Drills and Cutting Tools. Ball Nose Endmill Speeds and Feeds. This usually isnt necessary until seven degrees.

60 82 90 Drill Point. Calculations use the desired tool diameter. Bull Nose End Mill.

7 Flute End Mill for Dynamic Milling H. Includes miniature Square Ball and Corner Radius and Tapered end mills in a variety of diameters lengths of cut and overall reaches. 5 FLUTE 45 HELIX.

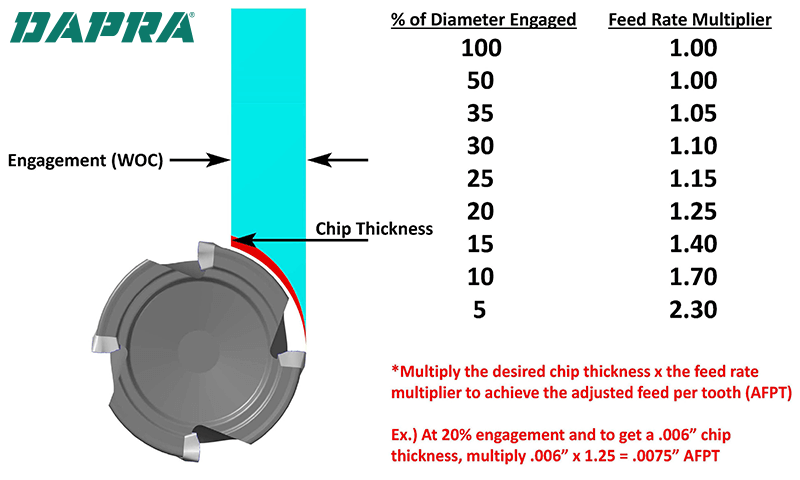

High Speed Machining Chip Thinning. Die Sinking End Mills. Determine the spindle speed RPM and feed rate IPM for a milling operation as well as the cut time for a given cut length.

Adjust speedsfeeds and width of cut to pull enough heat in chip. Performance of hard mills is dictated by heat evacuating in the chips. Tapping thread Engagement and Best Tap Drill selection for both Imperial and Metric Taps.

Low end of the FPT range. Square Radius Ball Nose End Mill. Im quoting a job 50 partswhere I have to create a groove in a knurldiamond pattern around a 26 dia.

2 Flute End Mills. The new Z-Carb HPR Five Flute Roughing End Mills are ideal for achieving high metal removal rates. End Mill Speeds And Feeds Chart - AlTiN Coated Carbide.

58 rows Melin Tool Company speed feed recommendations for high performance end. AMG - __-DP Series. For long and extra long tools reduce feed rates by 50.

Feeds and speeds for very small Router bits. Z-Carb-AP Advanced Performance End Mills. Series 7 High Performance End Mills - Long.

This will adjust the feedrate if. PREMIUM HSS MILL SPEED FEED Alloy Steels CHARTS Hardened Steels 430-710 Bhn 2-F1ute - Ball Nose - Material Hardness Diameter RI 64 x 132 RI32 x 116. Please fill out the form below with feeds and speeds that work for you and I will place them into a new database for all to use.

Radial Side Depth of Cut. Feed Hammer Mill is a key equipment for the production of pellets which composed of multiple components. Material is 6061-T6 aluminum.

They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Feed InchTooth End Mill Diameter 18 316 14 38 12 58 34 1 Recommendation for Coated Tools. 40 Helix Square and Ball End Mill.

Drilling and Tapping Speeds and Feeds. 3 Flute End Mills. Speeds Feeds Solid Carbide High Performance End Mills.

Miniature End Mills. The groove is 033 wide by 055 deep and has a 015 radius in the bottom of the groove. Routers for Aluminum.

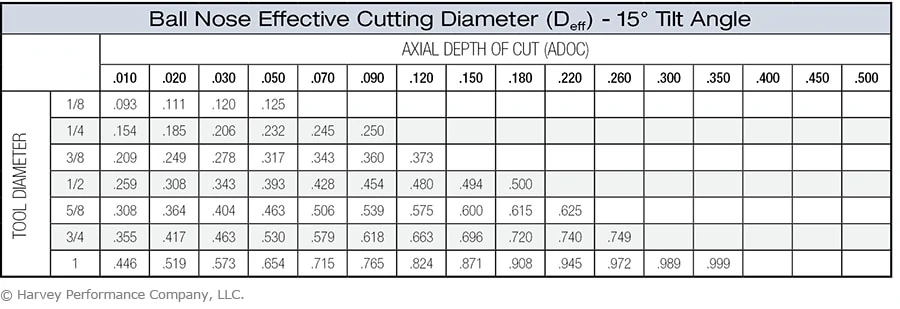

SMM SFM X 3048. The Adjusted Feedrate Chip Thinning Ball End Mill Effective Diameter Calculators are available in the tabs above. If you invest in a 132 tapered ball nosed end mill you will get something closer to.

For ball nose optimization and in addition to tilting the tool it is highly recommended to feed the tool in the direction of the incline and utilize a climb milling technique. In Oak - which is a really course grained wood - bits that small will not really yield anything that fine in detail any way - even if you do get it to work.

Ball Nose Milling Strategy Guide In The Loupe

Milling Speeds And Feeds Calculator Carbide End Mill Store

Carbide Endmill Feeds And Speeds

Ball Nose Milling Strategy Guide In The Loupe

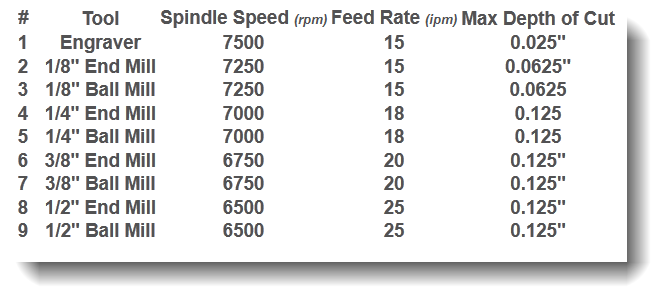

Shapeoko Feeds And Speeds Chart Reformatted

Amana Tool 51802 High Performance Cnc Solid Carbide Variable Helix Spiral Ball Nose With Altin Coating For Steel Stainless Steel Composites 3 16 R

Category Ma Ford Next Generation Tooling

The Skinny On End Mills Make Cnc Parts Cnc Machine Projects End Mill

Ball Nose Milling Strategy Guide In The Loupe

Ball End Mill An Overview Sciencedirect Topics

What Speeds And Feeds Do I Use On Wax Or Renshape Chris And Jim Cim

Ball Nose Milling Strategy Guide In The Loupe

Dynamic Spindle Speed And Feed Rate For Ball End Mill 3d Finishing Autodesk Community

Xcan Solid Carbide Ball Nose Tapered End Mills 2 Flute Engraving Router Bits Hrc55 Cnc Engraving Bit Wood Milling Cutter Milling Cutter Aliexpress